12s battery

A 12S battery pack is built from 12 cells connected in series, delivering a nominal voltage of 44.4V and up to 50.4V when fully charged. Depending on chemistry, a 12S LiPo battery provides high discharge rates for drones and UAVs, while a 12S lithium-ion battery offers higher energy density for longer endurance. Engineers and bulk buyers can choose the best 12S battery pack based on voltage, capacity, and application needs.

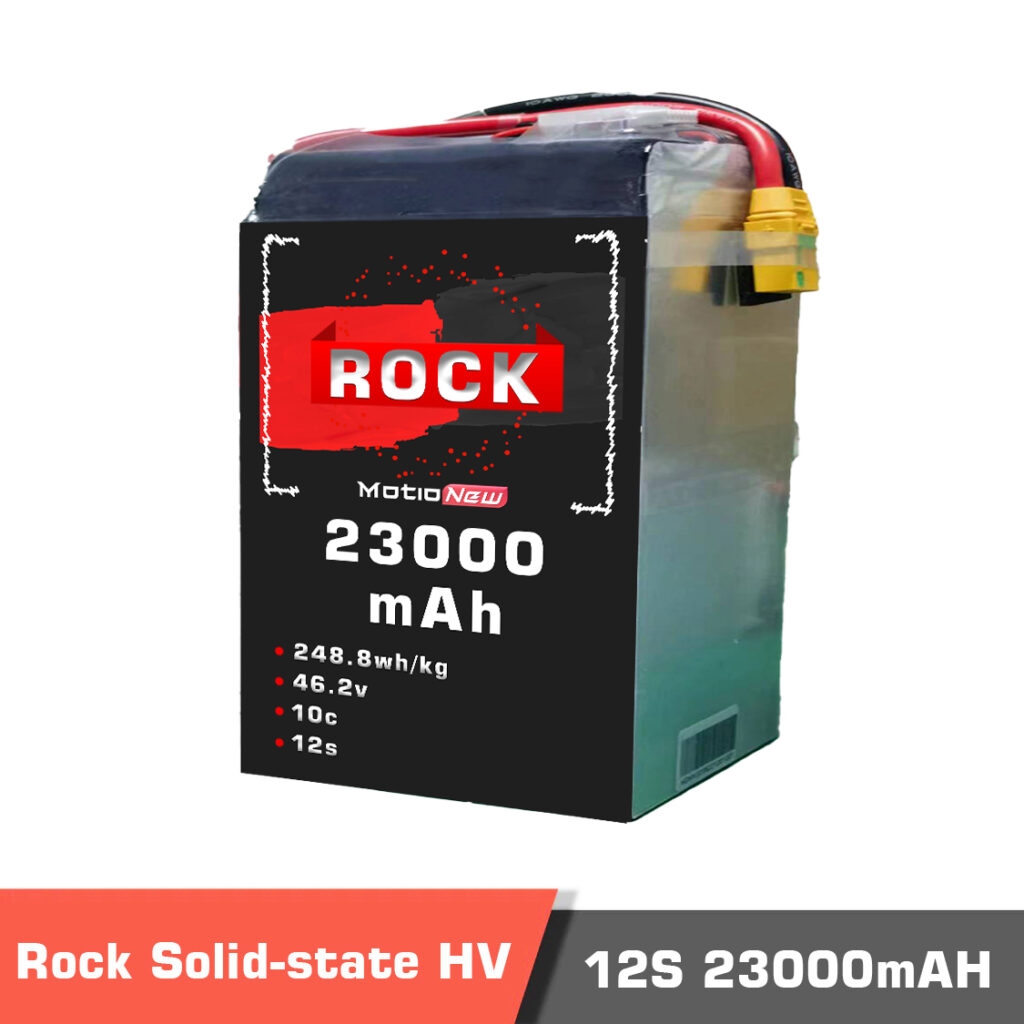

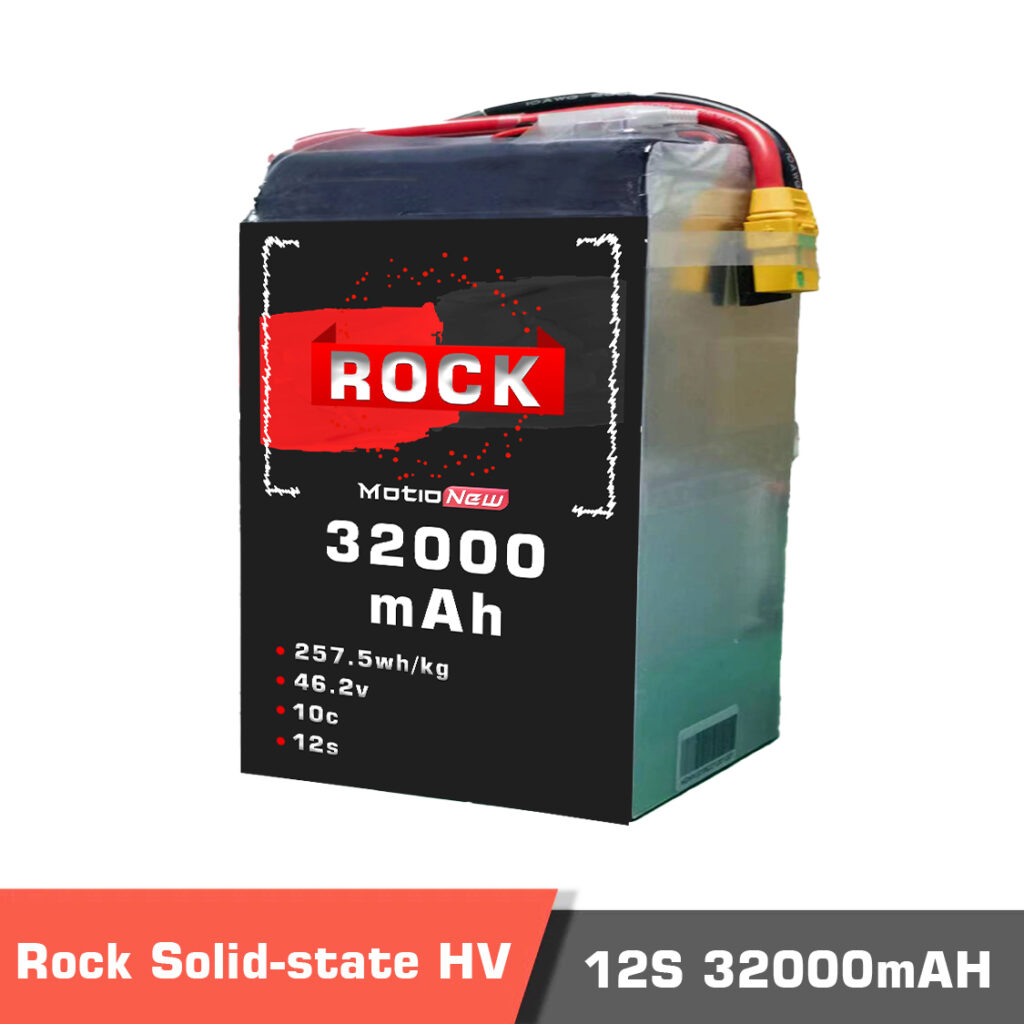

Solid-state batteries and semi solid-state batteries are manufactured in the form of a single cell. The capacity of each cell can be different, while their voltage level is the same. The maximum voltage level of each cell is 4.2v for normal batteries. High voltage batteries (HV batteries in short) have a maximum cell voltage of 4.25 ~ 4.35v, while ultra high voltage batteries (Ultra HV batteries) have maximum cell voltage of 4.45v. So what does it mean when we talk about 12s batteries? We will explain about them in the next few paragraphs.

Packing battery cells

The model of the final pack of the battery is highly dependent on the type of device that the battery is being used in. The cells can be connected in series or in parallel to generate the desired capacity and voltage. Connection in parallel increases the capacity of the battery pack, while series connection increases the voltage level. So when we talk about a 12S battery, it means that output voltage of the battery pack will be 12×4.2v=50.4v for normal batteries (or 53.4v for ultra high voltage batteries).

For example many smart devices like smart phones and tablets have CPU and IC that operate in low voltages, so they only need a single cell of battery. On the other hand, other devices may require 25v or 50v to operate, which means 6 or 12 cells should be connected in series to pack a 6S battery or a 12S battery respectively, to provide the required power.

Capacity of batteries

When we talk about the capacity of 12S batteries, what we refer to is the measurement of charge or Ampere-Hour (Ah) rating of the battery. It is simply a measure of how long a battery can provide one amp of power per hour. So the higher the Ampere-Hour of a battery, the longer it can work in when the same amount of current is drawn from it. Batteries with the same number of cells but with higher Ampere-Hour have higher weight and bigger size.

Choosing the optimum battery capacity for your drone

Drones and UAVs have many different electronic components that are powered using a battery. So it is important to choose the best voltage and capacity to first not damage the components, and second ensure the drone can fly for the desired duration of time.

One obvious solution would be why don’t we choose the highest available voltage and capacity? The answer to the first question is that all the electronic components have a rated voltage range and can only operate when the input to their system is within that range. The answer to the latter question is that as we mentioned, the higher the capacity of a battery pack, the higher its weight and dimensions will be.

For example a 12S battery pack of 30Ah capacity weighs 5200g while the same 12S pack with 66Ah capacity weights 10700g. This will cause some problems for the drone as they have a maximum take-off weight for operation which is decided based on the aerodynamics of the frame, and the propulsion system that is used. So it is important to always find the most optimum battery capacity for your drone operation.

Choosing the optimum battery voltage for your drone

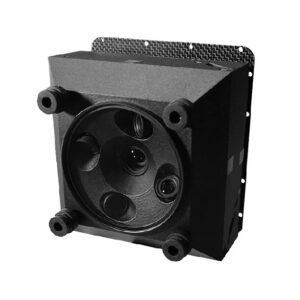

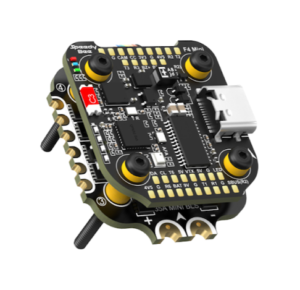

But how do we decide on the voltage level of the battery or its number of cells? As we mentioned, it will depend on the electronic components of the drone. All of the components of a drone including motors, ESC, flight controller and more have a maximum rated voltage. So the engineers should ensure that the maximum voltage of the battery pack will not exceed the maximum supported voltage of the drone components. Motors and ESC components used to work with 6S batteries, while now most of them are upgraded to 12S batteries which is more optimum and allows them to provide a higher thrust. More importantly, if you are going to use a high voltage or ultra high voltage 12S battery, you need to make sure that the motor and ESC support high voltage as their maximum voltage level will be higher than normal batteries.

On the other hand, other electronic components of the drone usually operate on much lower voltages than the voltage level of a 12S battery, so using a voltage regulator is necessary.

FAQ

What is the voltage of a 12S battery?

A 12S LiPo battery has a nominal voltage of 44.4V (12 × 3.7V) and a maximum of 50.4V when fully charged. High-voltage versions can reach above 52V.

What is the difference between a 12S LiPo battery and a 12S lithium-ion battery?

-

LiPo: lighter, higher discharge rate → better for propulsion and performance UAVs.

-

Lithium-ion: higher energy density, longer endurance → better for long missions.

What is a 12S battery pack used for?

12S packs are widely used in drones, UAVs, robotics, and industrial equipment that require ~44–50V operating voltage.

Can I use a 12S high-voltage pack in my drone?

Yes, but only if your motors, ESC, and flight controller support high-voltage input. Otherwise, voltage regulators are needed.

Browse our collection of 12S LiPo and lithium-ion battery packs below, or contact Motionew for bulk quotes and technical consultation to select the most suitable 12S battery for your UAV project.